Info@aspalengineering.com - GST NO. : 24ABACA4824G1Z2

- Send Email

Chemical Storage Tanks

Leading Manufacturers, Exporters, Wholesaler of Carbon Steel Chemical Storage Tank, Composite Chemical Storage Tank, FRP Chemical Storage Tank, Industrial Chemical Storage Tank, Polyethylene Chemical Storage Tank and Stainless Steel Chemical Storage Tank from Ahmedabad.

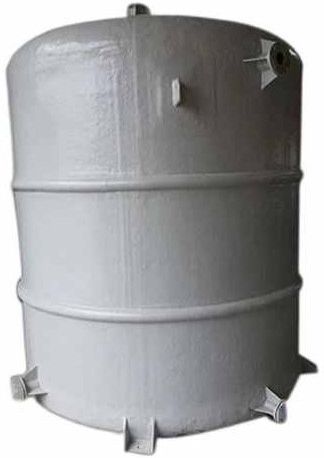

| Business Type | Manufacturer, Exporter, Supplier |

| Surface Finishing | Coated |

| Condition | New |

| Country of Origin | India |

| Automation Grade | Automatic |

| Type | Chemical Storage Tank |

| Material | Carbon Steel |

| Color | White |

| Capacity | 200L To 5000 L |

| Shape | Cylindrical |

| Application | Chemical Storage |

Types of Chemical Storage Tanks

1. Polyethylene Tanks:

Made from high-density polyethylene (HDPE) or cross-linked polyethylene (XLPE).

Resistant to a wide range of chemicals, including acids and bases.

Often used for storing corrosive chemicals.

2. Stainless Steel Tanks:

Constructed from various grades of stainless steel, offering excellent durability and corrosion resistance.

Suitable for storing highly corrosive chemicals and food-grade materials.

Often used in the food and beverage industry, pharmaceuticals, and water treatment.

3. Fiberglass-Reinforced Plastic (FRP) Tanks:

Made from a combination of fiberglass and resin, providing high strength and corrosion resistance.

Suitable for storing a variety of chemicals, including strong acids and caustics.

Common in the chemical processing and wastewater treatment industries.

4. Carbon Steel Tanks:

Made from carbon steel, often with a protective lining or coating to resist corrosion.

Suitable for storing flammable liquids and other less corrosive chemicals.

Used in oil and gas, and fuel storage applications.

5. Composite Tanks:

Combine different materials, such as a polyethylene inner layer with a fiberglass outer layer, to enhance chemical resistance and structural integrity.

Used for specific applications where both corrosion resistance and strength are required.

Why Choose Aspal Engineering for Storage Tanks?

Certified Quality: All tanks are manufactured as per IS standards, ensuring strength and reliability.

Material Options: Carbon steel, stainless steel, and custom alloys based on storage requirements.

Corrosion Resistant: Designed for long life in harsh chemical and industrial environments.

Custom Fabrication: Tailor-made tanks based on client specifications and industry needs.

On-time Delivery: Efficient production and installation support across India.

Design and Construction Considerations

1. Material Compatibility:

The tank material must be compatible with the chemicals being stored to prevent reactions that could compromise the tank's integrity.

2. Capacity and Size:

Tanks are available in various sizes, from small portable containers to large stationary tanks, depending on storage requirements.

3. Shape and Configuration:

Tanks can be cylindrical, rectangular, or custom-shaped.

Vertical tanks are common for space-saving, while horizontal tanks are used where height restrictions apply.

4. Safety Features:

Include venting systems, pressure relief valves, and secondary containment systems to prevent leaks and spills.

Double-walled tanks provide an additional layer of protection against leaks.

5. Temperature Control:

Some chemicals require temperature regulation to maintain stability, necessitating insulated or heated tanks.

6. Regulatory Compliance:

Tanks must meet industry standards and regulations, such as those set by the Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), and other local authorities.

Applications of Chemical Storage Tanks

Chemical Manufacturing: Storing raw materials, intermediates, and finished products.

Agriculture: Holding fertilizers, pesticides, and other agricultural chemicals.

Pharmaceuticals: Storing active ingredients, solvents, and other chemicals used in drug production.

Water Treatment: Containing chemicals like chlorine, alum, and acids used in water purification processes.

Food Processing: Storing ingredients, additives, and cleaning agents.

Maintenance and Safety Practices

1. Regular Inspections:

Conduct routine inspections to detect any signs of wear, corrosion, or damage.

2. Proper Labeling:

Clearly label tanks with the contents and associated hazards to ensure safe handling.

3. Spill Response Plan:

Have an emergency response plan in place to deal with spills or leaks promptly and effectively.

4. Training:

Train personnel on proper handling, storage, and emergency procedures related to the chemicals and storage tanks.

5. Ventilation and Monitoring:

Ensure proper ventilation and monitoring systems are in place to detect and manage any leaks or emissions.

Why We Stand Out as a Storage Tank Supplier in India

Aspal Engineering combines cutting-edge fabrication techniques with strict quality control. From reactors to custom fabrication works, we have earned a reputation for reliability and performance in the industrial sector.

| Business Type | Manufacturer, Exporter, Supplier |

| Condition | New |

| Warranty | 1 Years |

| Country of Origin | India |

| Type | Chemical Storage Tank |

| Material | Composite |

| Capacity | 500 L To 20000 L |

| Shape | Cylindrical Or Rectangular |

| Application | Chemical Storage |

| Maintenance | Regular Inspection Recommended |

| Certification | Complies With Industry Standards |

Types of Chemical Storage Tanks

1. Polyethylene Tanks:

Made from high-density polyethylene (HDPE) or cross-linked polyethylene (XLPE).

Resistant to a wide range of chemicals, including acids and bases.

Often used for storing corrosive chemicals.

2. Stainless Steel Tanks:

Constructed from various grades of stainless steel, offering excellent durability and corrosion resistance.

Suitable for storing highly corrosive chemicals and food-grade materials.

Often used in the food and beverage industry, pharmaceuticals, and water treatment.

3. Fiberglass-Reinforced Plastic (FRP) Tanks:

Made from a combination of fiberglass and resin, providing high strength and corrosion resistance.

Suitable for storing a variety of chemicals, including strong acids and caustics.

Common in the chemical processing and wastewater treatment industries.

4. Carbon Steel Tanks:

Made from carbon steel, often with a protective lining or coating to resist corrosion.

Suitable for storing flammable liquids and other less corrosive chemicals.

Used in oil and gas, and fuel storage applications.

5. Composite Tanks:

Combine different materials, such as a polyethylene inner layer with a fiberglass outer layer, to enhance chemical resistance and structural integrity.

Used for specific applications where both corrosion resistance and strength are required.

Why Choose Aspal Engineering for Storage Tanks?

Certified Quality: All tanks are manufactured as per IS standards, ensuring strength and reliability.

Material Options: Carbon steel, stainless steel, and custom alloys based on storage requirements.

Corrosion Resistant: Designed for long life in harsh chemical and industrial environments.

Custom Fabrication: Tailor-made tanks based on client specifications and industry needs.

On-time Delivery: Efficient production and installation support across India.

Design and Construction Considerations

1. Material Compatibility:

The tank material must be compatible with the chemicals being stored to prevent reactions that could compromise the tank's integrity.

2. Capacity and Size:

Tanks are available in various sizes, from small portable containers to large stationary tanks, depending on storage requirements.

3. Shape and Configuration:

Tanks can be cylindrical, rectangular, or custom-shaped.

Vertical tanks are common for space-saving, while horizontal tanks are used where height restrictions apply.

4. Safety Features:

Include venting systems, pressure relief valves, and secondary containment systems to prevent leaks and spills.

Double-walled tanks provide an additional layer of protection against leaks.

5. Temperature Control:

Some chemicals require temperature regulation to maintain stability, necessitating insulated or heated tanks.

6. Regulatory Compliance:

Tanks must meet industry standards and regulations, such as those set by the Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), and other local authorities.

Applications of Chemical Storage Tanks

Chemical Manufacturing: Storing raw materials, intermediates, and finished products.

Agriculture: Holding fertilizers, pesticides, and other agricultural chemicals.

Pharmaceuticals: Storing active ingredients, solvents, and other chemicals used in drug production.

Water Treatment: Containing chemicals like chlorine, alum, and acids used in water purification processes.

Food Processing: Storing ingredients, additives, and cleaning agents.

Maintenance and Safety Practices

1. Regular Inspections:

Conduct routine inspections to detect any signs of wear, corrosion, or damage.

2. Proper Labeling:

Clearly label tanks with the contents and associated hazards to ensure safe handling.

3. Spill Response Plan:

Have an emergency response plan in place to deal with spills or leaks promptly and effectively.

4. Training:

Train personnel on proper handling, storage, and emergency procedures related to the chemicals and storage tanks.

5. Ventilation and Monitoring:

Ensure proper ventilation and monitoring systems are in place to detect and manage any leaks or emissions.

Why We Stand Out as a Storage Tank Supplier in India

Aspal Engineering combines cutting-edge fabrication techniques with strict quality control. From reactors to custom fabrication works, we have earned a reputation for reliability and performance in the industrial sector.

| Business Type | Manufacturer, Exporter, Supplier |

| Condition | New |

| Certification | ISI Certified |

| Country of Origin | India |

| Automation Grade | Automatic |

| Type | Chemical Storage Tank |

| Material | FRP (Fiberglass Reinforced Plastic) |

| Color | White |

| Capacity | 1000-10000 Liters |

| Application | For Storing Chemicals In Industrial Applications |

Types of Chemical Storage Tanks

1. Polyethylene Tanks:

Made from high-density polyethylene (HDPE) or cross-linked polyethylene (XLPE).

Resistant to a wide range of chemicals, including acids and bases.

Often used for storing corrosive chemicals.

2. Stainless Steel Tanks:

Constructed from various grades of stainless steel, offering excellent durability and corrosion resistance.

Suitable for storing highly corrosive chemicals and food-grade materials.

Often used in the food and beverage industry, pharmaceuticals, and water treatment.

3. Fiberglass-Reinforced Plastic (FRP) Tanks:

Made from a combination of fiberglass and resin, providing high strength and corrosion resistance.

Suitable for storing a variety of chemicals, including strong acids and caustics.

Common in the chemical processing and wastewater treatment industries.

4. Carbon Steel Tanks:

Made from carbon steel, often with a protective lining or coating to resist corrosion.

Suitable for storing flammable liquids and other less corrosive chemicals.

Used in oil and gas, and fuel storage applications.

5. Composite Tanks:

Combine different materials, such as a polyethylene inner layer with a fiberglass outer layer, to enhance chemical resistance and structural integrity.

Used for specific applications where both corrosion resistance and strength are required.

Why Choose Aspal Engineering for Storage Tanks?

Certified Quality: All tanks are manufactured as per IS standards, ensuring strength and reliability.

Material Options: Carbon steel, stainless steel, and custom alloys based on storage requirements.

Corrosion Resistant: Designed for long life in harsh chemical and industrial environments.

Custom Fabrication: Tailor-made tanks based on client specifications and industry needs.

On-time Delivery: Efficient production and installation support across India.

Design and Construction Considerations

1. Material Compatibility:

The tank material must be compatible with the chemicals being stored to prevent reactions that could compromise the tank's integrity.

2. Capacity and Size:

Tanks are available in various sizes, from small portable containers to large stationary tanks, depending on storage requirements.

3. Shape and Configuration:

Tanks can be cylindrical, rectangular, or custom-shaped.

Vertical tanks are common for space-saving, while horizontal tanks are used where height restrictions apply.

4. Safety Features:

Include venting systems, pressure relief valves, and secondary containment systems to prevent leaks and spills.

Double-walled tanks provide an additional layer of protection against leaks.

5. Temperature Control:

Some chemicals require temperature regulation to maintain stability, necessitating insulated or heated tanks.

6. Regulatory Compliance:

Tanks must meet industry standards and regulations, such as those set by the Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), and other local authorities.

Applications of Chemical Storage Tanks

Chemical Manufacturing: Storing raw materials, intermediates, and finished products.

Agriculture: Holding fertilizers, pesticides, and other agricultural chemicals.

Pharmaceuticals: Storing active ingredients, solvents, and other chemicals used in drug production.

Water Treatment: Containing chemicals like chlorine, alum, and acids used in water purification processes.

Food Processing: Storing ingredients, additives, and cleaning agents.

Maintenance and Safety Practices

1. Regular Inspections:

Conduct routine inspections to detect any signs of wear, corrosion, or damage.

2. Proper Labeling:

Clearly label tanks with the contents and associated hazards to ensure safe handling.

3. Spill Response Plan:

Have an emergency response plan in place to deal with spills or leaks promptly and effectively.

4. Training:

Train personnel on proper handling, storage, and emergency procedures related to the chemicals and storage tanks.

5. Ventilation and Monitoring:

Ensure proper ventilation and monitoring systems are in place to detect and manage any leaks or emissions.

Why We Stand Out as a Storage Tank Supplier in India

Aspal Engineering combines cutting-edge fabrication techniques with strict quality control. From reactors to custom fabrication works, we have earned a reputation for reliability and performance in the industrial sector.

| Business Type | Manufacturer, Exporter, Supplier |

| Surface Finishing | Coated |

| Type | Storage Tank |

| Material | Steel |

| Capacity | 500 L TO 20000 L,Varies Based On Requirement |

| Application | Chemical Storage In Industrial Settings |

| Shape | Cylindrical Or Rectangular |

| Features | Chemical-resistant, Durable Construction |

Storage Tank Manufacturer in India – Chemical & Industrial Tanks

Aspal Engineering is a trusted Storage Tank Manufacturer in India, specializing in the design, fabrication, and supply of high-quality storage tanks for diverse industries. With years of expertise, advanced technology, and IS-certified standards, we deliver durable and cost-effective solutions for safe storage of chemicals, water, oils, gases, and other industrial fluids.

Types of Chemical Storage Tanks

1. Polyethylene Tanks:

Made from high-density polyethylene (HDPE) or cross-linked polyethylene (XLPE).

Resistant to a wide range of chemicals, including acids and bases.

Often used for storing corrosive chemicals.

2. Stainless Steel Tanks:

Constructed from various grades of stainless steel, offering excellent durability and corrosion resistance.

Suitable for storing highly corrosive chemicals and food-grade materials.

Often used in the food and beverage industry, pharmaceuticals, and water treatment.

3. Fiberglass-Reinforced Plastic (FRP) Tanks:

Made from a combination of fiberglass and resin, providing high strength and corrosion resistance.

Suitable for storing a variety of chemicals, including strong acids and caustics.

Common in the chemical processing and wastewater treatment industries.

4. Carbon Steel Tanks:

Made from carbon steel, often with a protective lining or coating to resist corrosion.

Suitable for storing flammable liquids and other less corrosive chemicals.

Used in oil and gas, and fuel storage applications.

5. Composite Tanks:

Combine different materials, such as a polyethylene inner layer with a fiberglass outer layer, to enhance chemical resistance and structural integrity.

Used for specific applications where both corrosion resistance and strength are required.

Why Choose Aspal Engineering for Storage Tanks?

Certified Quality: All tanks are manufactured as per IS standards, ensuring strength and reliability.

Material Options: Carbon steel, stainless steel, and custom alloys based on storage requirements.

Corrosion Resistant: Designed for long life in harsh chemical and industrial environments.

Custom Fabrication: Tailor-made tanks based on client specifications and industry needs.

On-time Delivery: Efficient production and installation support across India.

Design and Construction Considerations

1. Material Compatibility:

The tank material must be compatible with the chemicals being stored to prevent reactions that could compromise the tank's integrity.

2. Capacity and Size:

Tanks are available in various sizes, from small portable containers to large stationary tanks, depending on storage requirements.

3. Shape and Configuration:

Tanks can be cylindrical, rectangular, or custom-shaped.

Vertical tanks are common for space-saving, while horizontal tanks are used where height restrictions apply.

4. Safety Features:

Include venting systems, pressure relief valves, and secondary containment systems to prevent leaks and spills.

Double-walled tanks provide an additional layer of protection against leaks.

5. Temperature Control:

Some chemicals require temperature regulation to maintain stability, necessitating insulated or heated tanks.

6. Regulatory Compliance:

Tanks must meet industry standards and regulations, such as those set by the Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), and other local authorities.

Applications of Chemical Storage Tanks

Chemical Manufacturing: Storing raw materials, intermediates, and finished products.

Agriculture: Holding fertilizers, pesticides, and other agricultural chemicals.

Pharmaceuticals: Storing active ingredients, solvents, and other chemicals used in drug production.

Water Treatment: Containing chemicals like chlorine, alum, and acids used in water purification processes.

Food Processing: Storing ingredients, additives, and cleaning agents.

Maintenance and Safety Practices

1. Regular Inspections:

Conduct routine inspections to detect any signs of wear, corrosion, or damage.

2. Proper Labeling:

Clearly label tanks with the contents and associated hazards to ensure safe handling.

3. Spill Response Plan:

Have an emergency response plan in place to deal with spills or leaks promptly and effectively.

4. Training:

Train personnel on proper handling, storage, and emergency procedures related to the chemicals and storage tanks.

5. Ventilation and Monitoring:

Ensure proper ventilation and monitoring systems are in place to detect and manage any leaks or emissions.

Why We Stand Out as a Storage Tank Supplier in India

Aspal Engineering combines cutting-edge fabrication techniques with strict quality control. From reactors to custom fabrication works, we have earned a reputation for reliability and performance in the industrial sector.

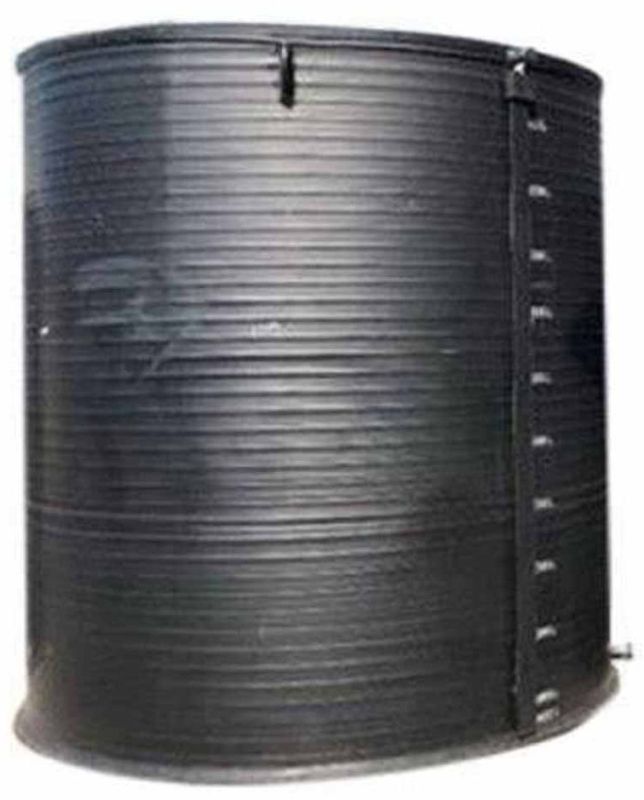

| Business Type | Manufacturer, Exporter, Supplier |

| Condition | New |

| Certification | ISI Certified |

| Capacity | 5000-10000L |

| Country of Origin | India |

| Type | Chemical Storage Tank |

| Material | Polyethylene |

| Color | Black |

| Shape | Round |

| Application | Chemical Storage |

| Features | Corrosion-resistant, UV-resistant |

| Maintenance | Regular Cleaning Recommended |

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Fully Automatic |

| Capacity | 1000-2000ltr |

| Power | 0-5Kw |

| Power Source | Electric |

| Warranty | 1 Year |

| Country of Origin | India |

| Type | Storage Tank |

| Material | Stainless Steel |

| Color | Black |

| Application | Chemical Storage |

Types of Chemical Storage Tanks

1. Polyethylene Tanks:

Made from high-density polyethylene (HDPE) or cross-linked polyethylene (XLPE).

Resistant to a wide range of chemicals, including acids and bases.

Often used for storing corrosive chemicals.

2. Stainless Steel Tanks:

Constructed from various grades of stainless steel, offering excellent durability and corrosion resistance.

Suitable for storing highly corrosive chemicals and food-grade materials.

Often used in the food and beverage industry, pharmaceuticals, and water treatment.

3. Fiberglass-Reinforced Plastic (FRP) Tanks:

Made from a combination of fiberglass and resin, providing high strength and corrosion resistance.

Suitable for storing a variety of chemicals, including strong acids and caustics.

Common in the chemical processing and wastewater treatment industries.

4. Carbon Steel Tanks:

Made from carbon steel, often with a protective lining or coating to resist corrosion.

Suitable for storing flammable liquids and other less corrosive chemicals.

Used in oil and gas, and fuel storage applications.

5. Composite Tanks:

Combine different materials, such as a polyethylene inner layer with a fiberglass outer layer, to enhance chemical resistance and structural integrity.

Used for specific applications where both corrosion resistance and strength are required.

Why Choose Aspal Engineering for Storage Tanks?

Certified Quality: All tanks are manufactured as per IS standards, ensuring strength and reliability.

Material Options: Carbon steel, stainless steel, and custom alloys based on storage requirements.

Corrosion Resistant: Designed for long life in harsh chemical and industrial environments.

Custom Fabrication: Tailor-made tanks based on client specifications and industry needs.

On-time Delivery: Efficient production and installation support across India.

Design and Construction Considerations

1. Material Compatibility:

The tank material must be compatible with the chemicals being stored to prevent reactions that could compromise the tank's integrity.

2. Capacity and Size:

Tanks are available in various sizes, from small portable containers to large stationary tanks, depending on storage requirements.

3. Shape and Configuration:

Tanks can be cylindrical, rectangular, or custom-shaped.

Vertical tanks are common for space-saving, while horizontal tanks are used where height restrictions apply.

4. Safety Features:

Include venting systems, pressure relief valves, and secondary containment systems to prevent leaks and spills.

Double-walled tanks provide an additional layer of protection against leaks.

5. Temperature Control:

Some chemicals require temperature regulation to maintain stability, necessitating insulated or heated tanks.

6. Regulatory Compliance:

Tanks must meet industry standards and regulations, such as those set by the Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), and other local authorities.

Applications of Chemical Storage Tanks

Chemical Manufacturing: Storing raw materials, intermediates, and finished products.

Agriculture: Holding fertilizers, pesticides, and other agricultural chemicals.

Pharmaceuticals: Storing active ingredients, solvents, and other chemicals used in drug production.

Water Treatment: Containing chemicals like chlorine, alum, and acids used in water purification processes.

Food Processing: Storing ingredients, additives, and cleaning agents.

Maintenance and Safety Practices

1. Regular Inspections:

Conduct routine inspections to detect any signs of wear, corrosion, or damage.

2. Proper Labeling:

Clearly label tanks with the contents and associated hazards to ensure safe handling.

3. Spill Response Plan:

Have an emergency response plan in place to deal with spills or leaks promptly and effectively.

4. Training:

Train personnel on proper handling, storage, and emergency procedures related to the chemicals and storage tanks.

5. Ventilation and Monitoring:

Ensure proper ventilation and monitoring systems are in place to detect and manage any leaks or emissions.

Why We Stand Out as a Storage Tank Supplier in India

Aspal Engineering combines cutting-edge fabrication techniques with strict quality control. From reactors to custom fabrication works, we have earned a reputation for reliability and performance in the industrial sector.