Info@aspalengineering.com - GST NO. : 24ABACA4824G1Z2

- Send Email

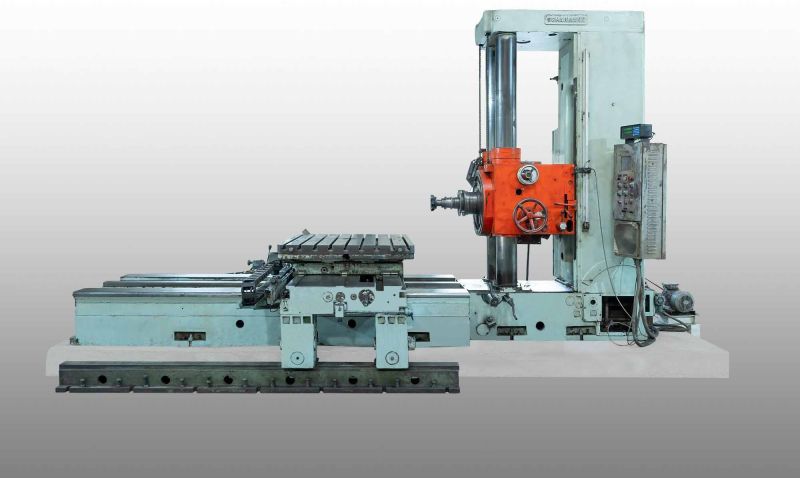

CNC Job Works

Leading Manufacturers, Exporters, Wholesaler of CNC Boring Services, CNC Drilling Tapping Service, CNC Milling Services, CNC Prototyping Service, CNC Surface Finishing Srvice, CNC Turning Services and Custom CNC Machining Service from Ahmedabad.

| Type | Service |

| Service Mode | Offline |

| Payment Mode | Online & Offline |

| Duration | Based On Various Projects |

| Advantages | Precision And Accuracy |

| Safety | Follow Proper Safety Guidelines |

| Maintenance | Regular Maintenance Required |

Advantages of CNC Machining

Precision and Accuracy: CNC machines can achieve extremely tight tolerances, ensuring high precision in parts.

Consistency and Repeatability: Once programmed, CNC machines can produce identical parts consistently without variation.

Efficiency and Productivity: CNC machines operate continuously with minimal supervision, leading to high production rates.

Versatility: Capable of handling a wide range of materials and complex geometries.

Reduced Human Error: Automation reduces the risk of human error and increases overall product quality.

Flexibility in Design: Easy to make changes to designs and implement them quickly through CNC programming.

Safety and Maintenance

Safety Protocols:

1.Follow proper safety guidelines, including the use of personal protective equipment (PPE).

2.Ensure safe operation of CNC machines and handling of cutting tools.

Regular Maintenance :

1. Perform routine maintenance to keep CNC machines in optimal condition.

2. Includes lubrication, cleaning, calibration, and inspection of components.

Training and Skill Development:

1. Provide training for operators on CNC machine operation, programming, and safety.

2. Encourage continuous learning to keep up with advancements in CNC technology.

CNC machining is a versatile and essential process in modern manufacturing, enabling the production of high-precision and complex parts across various industries. By leveraging the capabilities of CNC machines and adhering to best practices, manufacturers can achieve superior quality, efficiency, and innovation in their production processes.

| Service Mode | Offline |

| Payment Mode | Online & Offline |

| Duration | Based On Various Projects |

| Advantages | Precision And Accuracy |

| Safety | Follow Proper Safety Guidelines, Including The Use Of Personal Protective Equipment (PPE) |

| Maintenance | Regular Maintenance Required |

Advantages of CNC Machining

Precision and Accuracy: CNC machines can achieve extremely tight tolerances, ensuring high precision in parts.

Consistency and Repeatability: Once programmed, CNC machines can produce identical parts consistently without variation.

Efficiency and Productivity: CNC machines operate continuously with minimal supervision, leading to high production rates.

Versatility: Capable of handling a wide range of materials and complex geometries.

Reduced Human Error: Automation reduces the risk of human error and increases overall product quality.

Flexibility in Design: Easy to make changes to designs and implement them quickly through CNC programming.

Safety and Maintenance

Safety Protocols:

1.Follow proper safety guidelines, including the use of personal protective equipment (PPE).

2.Ensure safe operation of CNC machines and handling of cutting tools.

Regular Maintenance :

1. Perform routine maintenance to keep CNC machines in optimal condition.

2. Includes lubrication, cleaning, calibration, and inspection of components.

Training and Skill Development:

1. Provide training for operators on CNC machine operation, programming, and safety.

2. Encourage continuous learning to keep up with advancements in CNC technology.

CNC machining is a versatile and essential process in modern manufacturing, enabling the production of high-precision and complex parts across various industries. By leveraging the capabilities of CNC machines and adhering to best practices, manufacturers can achieve superior quality, efficiency, and innovation in their production processes.

| Type | CNC Milling Service |

| Service Mode | Offline |

| Payment Mode | Online & Offline |

| Duration | Based On Various Projects |

| Advantages | Precision And Accuracy |

| Safety | Follow Proper Safety Guidelines |

| Maintenance | Regular Maintenance Required |

Advantages of CNC Machining

Precision and Accuracy: CNC machines can achieve extremely tight tolerances, ensuring high precision in parts.

Consistency and Repeatability: Once programmed, CNC machines can produce identical parts consistently without variation.

Efficiency and Productivity: CNC machines operate continuously with minimal supervision, leading to high production rates.

Versatility: Capable of handling a wide range of materials and complex geometries.

Reduced Human Error: Automation reduces the risk of human error and increases overall product quality.

Flexibility in Design: Easy to make changes to designs and implement them quickly through CNC programming.

Safety and Maintenance

Safety Protocols:

1.Follow proper safety guidelines, including the use of personal protective equipment (PPE).

2.Ensure safe operation of CNC machines and handling of cutting tools.

Regular Maintenance :

1. Perform routine maintenance to keep CNC machines in optimal condition.

2. Includes lubrication, cleaning, calibration, and inspection of components.

Training and Skill Development:

1. Provide training for operators on CNC machine operation, programming, and safety.

2. Encourage continuous learning to keep up with advancements in CNC technology.

CNC machining is a versatile and essential process in modern manufacturing, enabling the production of high-precision and complex parts across various industries. By leveraging the capabilities of CNC machines and adhering to best practices, manufacturers can achieve superior quality, efficiency, and innovation in their production processes.

| Type | CNC Prototyping Service |

| Service Mode | Offline |

| Payment Mode | Online & Offline |

| Duration | Based On Various Projects |

| Advantages | Precision And Accuracy |

| Safety | Follow Proper Safety Guidelines |

| Maintenance | Regular Maintenance Required |

Advantages of CNC Machining

Precision and Accuracy: CNC machines can achieve extremely tight tolerances, ensuring high precision in parts.

Consistency and Repeatability: Once programmed, CNC machines can produce identical parts consistently without variation.

Efficiency and Productivity: CNC machines operate continuously with minimal supervision, leading to high production rates.

Versatility: Capable of handling a wide range of materials and complex geometries.

Reduced Human Error: Automation reduces the risk of human error and increases overall product quality.

Flexibility in Design: Easy to make changes to designs and implement them quickly through CNC programming.

Safety and Maintenance

Safety Protocols:

1.Follow proper safety guidelines, including the use of personal protective equipment (PPE).

2.Ensure safe operation of CNC machines and handling of cutting tools.

Regular Maintenance :

1. Perform routine maintenance to keep CNC machines in optimal condition.

2. Includes lubrication, cleaning, calibration, and inspection of components.

Training and Skill Development:

1. Provide training for operators on CNC machine operation, programming, and safety.

2. Encourage continuous learning to keep up with advancements in CNC technology.

CNC machining is a versatile and essential process in modern manufacturing, enabling the production of high-precision and complex parts across various industries. By leveraging the capabilities of CNC machines and adhering to best practices, manufacturers can achieve superior quality, efficiency, and innovation in their production processes.

| Service Mode | Offline |

| Payment Mode | Online & Offline |

| Duration | Based On Various Projects |

| Advantages | Precision And Accuracy |

| Safety | Follow Proper Safety Guidelines, Including The Use Of Personal Protective Equipment (PPE) |

| Maintenance | Regular Maintenance Required |

Advantages of CNC Machining

Precision and Accuracy: CNC machines can achieve extremely tight tolerances, ensuring high precision in parts.

Consistency and Repeatability: Once programmed, CNC machines can produce identical parts consistently without variation.

Efficiency and Productivity: CNC machines operate continuously with minimal supervision, leading to high production rates.

Versatility: Capable of handling a wide range of materials and complex geometries.

Reduced Human Error: Automation reduces the risk of human error and increases overall product quality.

Flexibility in Design: Easy to make changes to designs and implement them quickly through CNC programming.

Safety and Maintenance

Safety Protocols:

1.Follow proper safety guidelines, including the use of personal protective equipment (PPE).

2.Ensure safe operation of CNC machines and handling of cutting tools.

Regular Maintenance :

1. Perform routine maintenance to keep CNC machines in optimal condition.

2. Includes lubrication, cleaning, calibration, and inspection of components.

Training and Skill Development:

1. Provide training for operators on CNC machine operation, programming, and safety.

2. Encourage continuous learning to keep up with advancements in CNC technology.

CNC machining is a versatile and essential process in modern manufacturing, enabling the production of high-precision and complex parts across various industries. By leveraging the capabilities of CNC machines and adhering to best practices, manufacturers can achieve superior quality, efficiency, and innovation in their production processes.

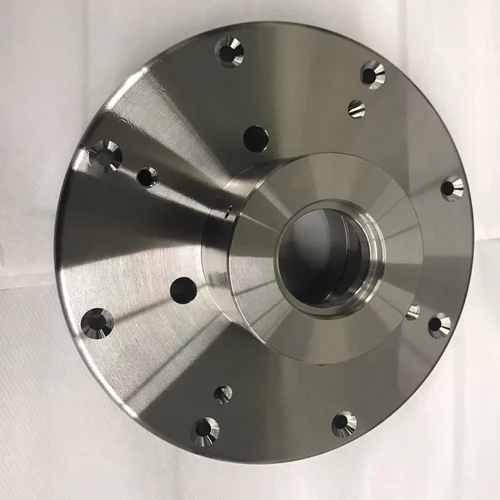

| Type | CNC Turning Services |

| Service Mode | Offline |

| Payment Mode | Online & Offline |

| Duration | Based On Various Projects |

| Advantages | Precision And Accuracy |

| Safety | Follow Proper Safety Guidelines, Including The Use Of Personal Protective Equipment (PPE) |

| Maintenance | Regular Maintenance Required |

Advantages of CNC Machining

Precision and Accuracy: CNC machines can achieve extremely tight tolerances, ensuring high precision in parts.

Consistency and Repeatability: Once programmed, CNC machines can produce identical parts consistently without variation.

Efficiency and Productivity: CNC machines operate continuously with minimal supervision, leading to high production rates.

Versatility: Capable of handling a wide range of materials and complex geometries.

Reduced Human Error: Automation reduces the risk of human error and increases overall product quality.

Flexibility in Design: Easy to make changes to designs and implement them quickly through CNC programming.

Safety and Maintenance

Safety Protocols:

1.Follow proper safety guidelines, including the use of personal protective equipment (PPE).

2.Ensure safe operation of CNC machines and handling of cutting tools.

Regular Maintenance :

1. Perform routine maintenance to keep CNC machines in optimal condition.

2. Includes lubrication, cleaning, calibration, and inspection of components.

Training and Skill Development:

1. Provide training for operators on CNC machine operation, programming, and safety.

2. Encourage continuous learning to keep up with advancements in CNC technology.

CNC machining is a versatile and essential process in modern manufacturing, enabling the production of high-precision and complex parts across various industries. By leveraging the capabilities of CNC machines and adhering to best practices, manufacturers can achieve superior quality, efficiency, and innovation in their production processes.

| Type | Custom CNC Machining Service |

| Service Mode | Offline |

| Payment Mode | Online & Offline |

| Duration | Based On Various Projects |

| Advantages | Precision And Accuracy |

| Safety | Follow Proper Safety Guidelines |

| Maintenance | Regular Maintenance Required |

Advantages of CNC Machining

Precision and Accuracy: CNC machines can achieve extremely tight tolerances, ensuring high precision in parts.

Consistency and Repeatability: Once programmed, CNC machines can produce identical parts consistently without variation.

Efficiency and Productivity: CNC machines operate continuously with minimal supervision, leading to high production rates.

Versatility: Capable of handling a wide range of materials and complex geometries.

Reduced Human Error: Automation reduces the risk of human error and increases overall product quality.

Flexibility in Design: Easy to make changes to designs and implement them quickly through CNC programming.

Safety and Maintenance

Safety Protocols:

1.Follow proper safety guidelines, including the use of personal protective equipment (PPE).

2.Ensure safe operation of CNC machines and handling of cutting tools.

Regular Maintenance :

1. Perform routine maintenance to keep CNC machines in optimal condition.

2. Includes lubrication, cleaning, calibration, and inspection of components.

Training and Skill Development:

1. Provide training for operators on CNC machine operation, programming, and safety.

2. Encourage continuous learning to keep up with advancements in CNC technology.

CNC machining is a versatile and essential process in modern manufacturing, enabling the production of high-precision and complex parts across various industries. By leveraging the capabilities of CNC machines and adhering to best practices, manufacturers can achieve superior quality, efficiency, and innovation in their production processes.