Info@aspalengineering.com - GST NO. : 24ABACA4824G1Z2

- Send Email

Industrial Reactors

Leading Manufacturers, Exporters, Wholesaler of Automatic Photochemical Reactor, Chemical Batch Reactor, Membrane Bio Chemical Reactor, Mild Steel Semi Batch Chemical Reactor, Packed Bed Reactor, Stainless Steel Chemical Reactors, Stainless Steel Continuous Flow Reactor and Stainless Steel Fluidized Bed Chemical Reactor from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Automation Grade | Automatic |

| Origin | India |

| Material | Glass And Stainless Steel |

| Packaging | Secure Packaging For Safe Transportation |

| Usage | Used For Photochemical Reactions In Research Labs |

| Capacity | 100ml To 5L |

| Power Source | Electricity |

| Control System | Automated Control System For Precise Operation |

| Safety Features | Built-in Safety Mechanisms For User Protection |

| Additional Features | Integrated Cooling System For Temperature Control |

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Chemical Batch Reactor |

| Material | Stainless Steel |

| Color | Silver |

| Capacity | 200 To 5000 Liters |

| Application | Mixing And Chemical Reactions |

| Temperature Range | Room Temperature To 200°C |

| Pressure Range | Atmospheric Pressure To 5 Bar |

| Accessories | Stirrer, Temperature Probe |

| Safety Features | Pressure Release Valve |

Reactors

Reactors are critical components in chemical engineering and various industries, designed to facilitate controlled chemical reactions. These reactors come in different types and configurations, each suited for specific reaction conditions and requirements. They play a vital role in the production of chemicals, pharmaceuticals, polymers, and many other products.

Types of Chemical Reactors

1. Batch Reactors:

Operate with all reactants loaded into the reactor at the start, and products are removed after the reaction is complete.

Suitable for small-scale production and processes that require precise control over reaction time and conditions.

Commonly used in pharmaceuticals, fine chemicals, and specialty chemicals.

2. Continuous Flow Reactors:

Reactants are continuously fed into the reactor, and products are continuously removed.

Suitable for large-scale production and processes that benefit from steady-state conditions.

Types include:

Plug Flow Reactors (PFR): Also known as tubular reactors, these have a continuous flow of reactants through a cylindrical pipe. Ideal for reactions with a consistent reaction rate along the length of the reactor.

Continuous Stirred-Tank Reactors (CSTR): Also known as mixed flow reactors, these have a constant flow of reactants and products with continuous mixing. Suitable for reactions that need uniform composition throughout the reactor.

3. Semi-Batch Reactors:

A combination of batch and continuous operations, where one or more reactants are added continuously or in stages, while the product is removed batch-wise.

Used for reactions that require gradual addition of a reactant to control reaction rate and heat generation.

4. Packed Bed Reactors:

Consist of a packed bed of catalyst particles, through which the reactants flow.

Commonly used in catalytic processes where the reaction occurs on the surface of solid catalysts.

Widely used in petrochemical, pharmaceutical, and environmental applications.

5. Fluidized Bed Reactors:

Solid catalyst particles are suspended in an upward flow of gas or liquid, creating a fluid-like state.

Provides excellent heat and mass transfer, suitable for reactions requiring uniform temperature and catalyst distribution.

Used in processes like catalytic cracking in the petroleum industry.

6. Membrane Reactors:

Combine reaction and separation in a single unit by using a membrane to selectively separate products or reactants.

Enhance reaction efficiency and selectivity, often used in hydrogen production and purification processes.

7. Photo Reactors:

Utilize light (usually UV or visible light) to initiate and drive chemical reactions.

Used in processes like photopolymerization, photocatalysis, and synthesis of fine chemicals.

8. Microreactors:

Miniaturized reactors with small channels or chambers, allowing precise control over reaction conditions.

Suitable for fast, exothermic reactions and research and development of new processes.

Applications of Chemical Reactors

Chemical Manufacturing: Production of bulk chemicals, intermediates, and specialty chemicals.

Pharmaceutical Industry: Synthesis of active pharmaceutical ingredients (APIs) and drug formulations.

Petrochemical Industry: Refining of crude oil, production of fuels, and petrochemical intermediates.

Polymer Production: Manufacture of plastics, resins, and synthetic fibers.

Environmental Applications: Treatment of wastewater, air pollution control, and catalytic converters.

Design and Operational Considerations

1. Reaction Kinetics:

Understanding the rate of reaction and how it changes with concentration and temperature is crucial for reactor design.

2. Heat and Mass Transfer:

Efficient transfer of heat and mass within the reactor is essential to maintain optimal reaction conditions and avoid hotspots or concentration gradients.

3. Material Selection:

The choice of materials for reactor construction must be compatible with the reactants, products, and operating conditions to ensure durability and safety.

4. Safety and Control:

Reactors must be equipped with appropriate safety measures, including pressure relief systems, temperature and pressure sensors, and emergency shutdown systems.

5. Scalability:

The reactor design should consider scalability from laboratory to pilot plant to full-scale production.

6. Cost Efficiency:

Optimizing reactor design and operation to minimize costs while maximizing yield and productivity is essential for commercial viability.

Advancements in Reactor Technology

Catalyst Development: Enhancing catalyst performance to improve reaction rates and selectivity.

Process Intensification: Designing more compact and efficient reactors to increase throughput and reduce energy consumption.

Automation and Control: Implementing advanced control systems for real-time monitoring and optimization of reactor operations.

Sustainable Processes: Developing reactors that use renewable energy sources, reduce waste, and minimize environmental impact.

Chemical reactors are the heart of industrial chemical processes, and their design and operation are critical to the efficiency, safety, and economic viability of chemical production. Understanding the different types of reactors and their specific applications helps in selecting the right reactor for a given process, ensuring optimal performance and sustainability.

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Semi-Automatic |

| Country of Origin | India |

| Type | Water Treatment Equipment |

| Material | Stainless Steel |

| Color | Silver |

| Usage | Wastewater Treatment |

| Power Source | Electricity |

Reactors

Reactors are critical components in chemical engineering and various industries, designed to facilitate controlled chemical reactions. These reactors come in different types and configurations, each suited for specific reaction conditions and requirements. They play a vital role in the production of chemicals, pharmaceuticals, polymers, and many other products.

Types of Chemical Reactors

1. Batch Reactors:

Operate with all reactants loaded into the reactor at the start, and products are removed after the reaction is complete.

Suitable for small-scale production and processes that require precise control over reaction time and conditions.

Commonly used in pharmaceuticals, fine chemicals, and specialty chemicals.

2. Continuous Flow Reactors:

Reactants are continuously fed into the reactor, and products are continuously removed.

Suitable for large-scale production and processes that benefit from steady-state conditions.

Types include:

Plug Flow Reactors (PFR): Also known as tubular reactors, these have a continuous flow of reactants through a cylindrical pipe. Ideal for reactions with a consistent reaction rate along the length of the reactor.

Continuous Stirred-Tank Reactors (CSTR): Also known as mixed flow reactors, these have a constant flow of reactants and products with continuous mixing. Suitable for reactions that need uniform composition throughout the reactor.

3. Semi-Batch Reactors:

A combination of batch and continuous operations, where one or more reactants are added continuously or in stages, while the product is removed batch-wise.

Used for reactions that require gradual addition of a reactant to control reaction rate and heat generation.

4. Packed Bed Reactors:

Consist of a packed bed of catalyst particles, through which the reactants flow.

Commonly used in catalytic processes where the reaction occurs on the surface of solid catalysts.

Widely used in petrochemical, pharmaceutical, and environmental applications.

5. Fluidized Bed Reactors:

Solid catalyst particles are suspended in an upward flow of gas or liquid, creating a fluid-like state.

Provides excellent heat and mass transfer, suitable for reactions requiring uniform temperature and catalyst distribution.

Used in processes like catalytic cracking in the petroleum industry.

6. Membrane Reactors:

Combine reaction and separation in a single unit by using a membrane to selectively separate products or reactants.

Enhance reaction efficiency and selectivity, often used in hydrogen production and purification processes.

7. Photo Reactors:

Utilize light (usually UV or visible light) to initiate and drive chemical reactions.

Used in processes like photopolymerization, photocatalysis, and synthesis of fine chemicals.

8. Microreactors:

Miniaturized reactors with small channels or chambers, allowing precise control over reaction conditions.

Suitable for fast, exothermic reactions and research and development of new processes.

Applications of Chemical Reactors

Chemical Manufacturing: Production of bulk chemicals, intermediates, and specialty chemicals.

Pharmaceutical Industry: Synthesis of active pharmaceutical ingredients (APIs) and drug formulations.

Petrochemical Industry: Refining of crude oil, production of fuels, and petrochemical intermediates.

Polymer Production: Manufacture of plastics, resins, and synthetic fibers.

Environmental Applications: Treatment of wastewater, air pollution control, and catalytic converters.

Design and Operational Considerations

1. Reaction Kinetics:

Understanding the rate of reaction and how it changes with concentration and temperature is crucial for reactor design.

2. Heat and Mass Transfer:

Efficient transfer of heat and mass within the reactor is essential to maintain optimal reaction conditions and avoid hotspots or concentration gradients.

3. Material Selection:

The choice of materials for reactor construction must be compatible with the reactants, products, and operating conditions to ensure durability and safety.

4. Safety and Control:

Reactors must be equipped with appropriate safety measures, including pressure relief systems, temperature and pressure sensors, and emergency shutdown systems.

5. Scalability:

The reactor design should consider scalability from laboratory to pilot plant to full-scale production.

6. Cost Efficiency:

Optimizing reactor design and operation to minimize costs while maximizing yield and productivity is essential for commercial viability.

Advancements in Reactor Technology

Catalyst Development: Enhancing catalyst performance to improve reaction rates and selectivity.

Process Intensification: Designing more compact and efficient reactors to increase throughput and reduce energy consumption.

Automation and Control: Implementing advanced control systems for real-time monitoring and optimization of reactor operations.

Sustainable Processes: Developing reactors that use renewable energy sources, reduce waste, and minimize environmental impact.

Chemical reactors are the heart of industrial chemical processes, and their design and operation are critical to the efficiency, safety, and economic viability of chemical production. Understanding the different types of reactors and their specific applications helps in selecting the right reactor for a given process, ensuring optimal performance and sustainability.

| Business Type | Manufacturer, Exporter, Supplier |

| Automation Grade | Automatic |

| Finishing | Polished |

| Type | Chemical Reactor |

| Material | Mild Steel |

| Color | White, Blue |

| Usage/Application | Chemical Processing |

| Shape | Cylindrical |

| Temperature Range | Room Temperature To High |

| Pressure Range | Low To High Pressure |

| Feature | Semi-batch Operation |

Reactors

Reactors are critical components in chemical engineering and various industries, designed to facilitate controlled chemical reactions. These reactors come in different types and configurations, each suited for specific reaction conditions and requirements. They play a vital role in the production of chemicals, pharmaceuticals, polymers, and many other products.

Types of Chemical Reactors

1. Batch Reactors:

Operate with all reactants loaded into the reactor at the start, and products are removed after the reaction is complete.

Suitable for small-scale production and processes that require precise control over reaction time and conditions.

Commonly used in pharmaceuticals, fine chemicals, and specialty chemicals.

2. Continuous Flow Reactors:

Reactants are continuously fed into the reactor, and products are continuously removed.

Suitable for large-scale production and processes that benefit from steady-state conditions.

Types include:

Plug Flow Reactors (PFR): Also known as tubular reactors, these have a continuous flow of reactants through a cylindrical pipe. Ideal for reactions with a consistent reaction rate along the length of the reactor.

Continuous Stirred-Tank Reactors (CSTR): Also known as mixed flow reactors, these have a constant flow of reactants and products with continuous mixing. Suitable for reactions that need uniform composition throughout the reactor.

3. Semi-Batch Reactors:

A combination of batch and continuous operations, where one or more reactants are added continuously or in stages, while the product is removed batch-wise.

Used for reactions that require gradual addition of a reactant to control reaction rate and heat generation.

4. Packed Bed Reactors:

Consist of a packed bed of catalyst particles, through which the reactants flow.

Commonly used in catalytic processes where the reaction occurs on the surface of solid catalysts.

Widely used in petrochemical, pharmaceutical, and environmental applications.

5. Fluidized Bed Reactors:

Solid catalyst particles are suspended in an upward flow of gas or liquid, creating a fluid-like state.

Provides excellent heat and mass transfer, suitable for reactions requiring uniform temperature and catalyst distribution.

Used in processes like catalytic cracking in the petroleum industry.

6. Membrane Reactors:

Combine reaction and separation in a single unit by using a membrane to selectively separate products or reactants.

Enhance reaction efficiency and selectivity, often used in hydrogen production and purification processes.

7. Photo Reactors:

Utilize light (usually UV or visible light) to initiate and drive chemical reactions.

Used in processes like photopolymerization, photocatalysis, and synthesis of fine chemicals.

8. Microreactors:

Miniaturized reactors with small channels or chambers, allowing precise control over reaction conditions.

Suitable for fast, exothermic reactions and research and development of new processes.

Applications of Chemical Reactors

Chemical Manufacturing: Production of bulk chemicals, intermediates, and specialty chemicals.

Pharmaceutical Industry: Synthesis of active pharmaceutical ingredients (APIs) and drug formulations.

Petrochemical Industry: Refining of crude oil, production of fuels, and petrochemical intermediates.

Polymer Production: Manufacture of plastics, resins, and synthetic fibers.

Environmental Applications: Treatment of wastewater, air pollution control, and catalytic converters.

Design and Operational Considerations

1. Reaction Kinetics:

Understanding the rate of reaction and how it changes with concentration and temperature is crucial for reactor design.

2. Heat and Mass Transfer:

Efficient transfer of heat and mass within the reactor is essential to maintain optimal reaction conditions and avoid hotspots or concentration gradients.

3. Material Selection:

The choice of materials for reactor construction must be compatible with the reactants, products, and operating conditions to ensure durability and safety.

4. Safety and Control:

Reactors must be equipped with appropriate safety measures, including pressure relief systems, temperature and pressure sensors, and emergency shutdown systems.

5. Scalability:

The reactor design should consider scalability from laboratory to pilot plant to full-scale production.

6. Cost Efficiency:

Optimizing reactor design and operation to minimize costs while maximizing yield and productivity is essential for commercial viability.

Advancements in Reactor Technology

Catalyst Development: Enhancing catalyst performance to improve reaction rates and selectivity.

Process Intensification: Designing more compact and efficient reactors to increase throughput and reduce energy consumption.

Automation and Control: Implementing advanced control systems for real-time monitoring and optimization of reactor operations.

Sustainable Processes: Developing reactors that use renewable energy sources, reduce waste, and minimize environmental impact.

Chemical reactors are the heart of industrial chemical processes, and their design and operation are critical to the efficiency, safety, and economic viability of chemical production. Understanding the different types of reactors and their specific applications helps in selecting the right reactor for a given process, ensuring optimal performance and sustainability.

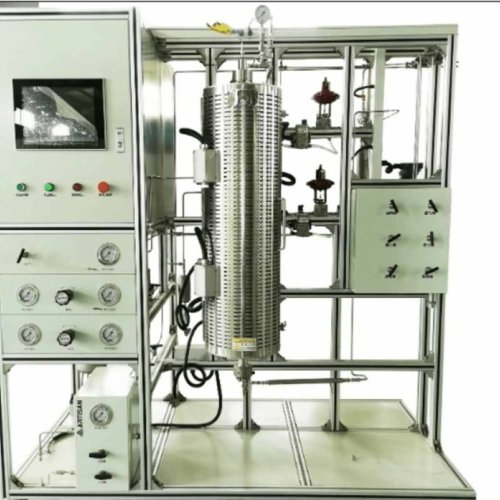

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Automatic |

| Voltage | 220V |

| Warranty | 1 Year |

| Country of Origin | India |

| Type | Chemical Reactor |

| Material | Stainless Steel |

| Application | Chemical Processing |

| Shape | Cylindrical |

| Temperature Range | High Temperature Range |

| Business Type | Manufacturer, Exporter, Supplier |

| Storage Capacity | 200L To 5000 L |

| Type | Chemical Reactors |

| Material | Stainless Steel |

| Color | Silver |

| Usage/Application | Facilitate Controlled Chemical Reactions |

| SuitableFor | Chemical Engineering And Various Industries |

| Applications | Chemical Manufacturing, Pharmaceutical Industry, Petrochemical Industry |

| Design Considerations | Reaction Kinetics, Heat And Mass Transfer, Material Selection |

Reactors

Reactors are critical components in chemical engineering and various industries, designed to facilitate controlled chemical reactions. These reactors come in different types and configurations, each suited for specific reaction conditions and requirements. They play a vital role in the production of chemicals, pharmaceuticals, polymers, and many other products.

Types of Chemical Reactors

1. Batch Reactors:

Operate with all reactants loaded into the reactor at the start, and products are removed after the reaction is complete.

Suitable for small-scale production and processes that require precise control over reaction time and conditions.

Commonly used in pharmaceuticals, fine chemicals, and specialty chemicals.

2. Continuous Flow Reactors:

Reactants are continuously fed into the reactor, and products are continuously removed.

Suitable for large-scale production and processes that benefit from steady-state conditions.

Types include:

Plug Flow Reactors (PFR): Also known as tubular reactors, these have a continuous flow of reactants through a cylindrical pipe. Ideal for reactions with a consistent reaction rate along the length of the reactor.

Continuous Stirred-Tank Reactors (CSTR): Also known as mixed flow reactors, these have a constant flow of reactants and products with continuous mixing. Suitable for reactions that need uniform composition throughout the reactor.

3. Semi-Batch Reactors:

A combination of batch and continuous operations, where one or more reactants are added continuously or in stages, while the product is removed batch-wise.

Used for reactions that require gradual addition of a reactant to control reaction rate and heat generation.

4. Packed Bed Reactors:

Consist of a packed bed of catalyst particles, through which the reactants flow.

Commonly used in catalytic processes where the reaction occurs on the surface of solid catalysts.

Widely used in petrochemical, pharmaceutical, and environmental applications.

5. Fluidized Bed Reactors:

Solid catalyst particles are suspended in an upward flow of gas or liquid, creating a fluid-like state.

Provides excellent heat and mass transfer, suitable for reactions requiring uniform temperature and catalyst distribution.

Used in processes like catalytic cracking in the petroleum industry.

6. Membrane Reactors:

Combine reaction and separation in a single unit by using a membrane to selectively separate products or reactants.

Enhance reaction efficiency and selectivity, often used in hydrogen production and purification processes.

7. Photo Reactors:

Utilize light (usually UV or visible light) to initiate and drive chemical reactions.

Used in processes like photopolymerization, photocatalysis, and synthesis of fine chemicals.

8. Microreactors:

Miniaturized reactors with small channels or chambers, allowing precise control over reaction conditions.

Suitable for fast, exothermic reactions and research and development of new processes.

Applications of Chemical Reactors

Chemical Manufacturing: Production of bulk chemicals, intermediates, and specialty chemicals.

Pharmaceutical Industry: Synthesis of active pharmaceutical ingredients (APIs) and drug formulations.

Petrochemical Industry: Refining of crude oil, production of fuels, and petrochemical intermediates.

Polymer Production: Manufacture of plastics, resins, and synthetic fibers.

Environmental Applications: Treatment of wastewater, air pollution control, and catalytic converters.

Design and Operational Considerations

1. Reaction Kinetics:

Understanding the rate of reaction and how it changes with concentration and temperature is crucial for reactor design.

2. Heat and Mass Transfer:

Efficient transfer of heat and mass within the reactor is essential to maintain optimal reaction conditions and avoid hotspots or concentration gradients.

3. Material Selection:

The choice of materials for reactor construction must be compatible with the reactants, products, and operating conditions to ensure durability and safety.

4. Safety and Control:

Reactors must be equipped with appropriate safety measures, including pressure relief systems, temperature and pressure sensors, and emergency shutdown systems.

5. Scalability:

The reactor design should consider scalability from laboratory to pilot plant to full-scale production.

6. Cost Efficiency:

Optimizing reactor design and operation to minimize costs while maximizing yield and productivity is essential for commercial viability.

Advancements in Reactor Technology

Catalyst Development: Enhancing catalyst performance to improve reaction rates and selectivity.

Process Intensification: Designing more compact and efficient reactors to increase throughput and reduce energy consumption.

Automation and Control: Implementing advanced control systems for real-time monitoring and optimization of reactor operations.

Sustainable Processes: Developing reactors that use renewable energy sources, reduce waste, and minimize environmental impact.

Chemical reactors are the heart of industrial chemical processes, and their design and operation are critical to the efficiency, safety, and economic viability of chemical production. Understanding the different types of reactors and their specific applications helps in selecting the right reactor for a given process, ensuring optimal performance and sustainability.

| Business Type | Manufacturer, Exporter, Supplier |

| Material Grade | SS304 |

| Automation Grade | Automatic |

| Finishing | Polished |

| Warranty | 1year |

| Country of Origin | India |

| Type | Continuous Flow Reactor |

| Material | Stainless Steel |

| Color | Silver |

| Usage/Application | Chemical Reactions |

| Suitable For | Large-scale Production |

| Applications | Chemical Manufacturing, Pharmaceutical Industry, Petrochemical Industry, Polymer Production, Environmental Applications |

Reactors

Reactors are critical components in chemical engineering and various industries, designed to facilitate controlled chemical reactions. These reactors come in different types and configurations, each suited for specific reaction conditions and requirements. They play a vital role in the production of chemicals, pharmaceuticals, polymers, and many other products.

Types of Chemical Reactors

1. Batch Reactors:

Operate with all reactants loaded into the reactor at the start, and products are removed after the reaction is complete.

Suitable for small-scale production and processes that require precise control over reaction time and conditions.

Commonly used in pharmaceuticals, fine chemicals, and specialty chemicals.

2. Continuous Flow Reactors:

Reactants are continuously fed into the reactor, and products are continuously removed.

Suitable for large-scale production and processes that benefit from steady-state conditions.

Types include:

Plug Flow Reactors (PFR): Also known as tubular reactors, these have a continuous flow of reactants through a cylindrical pipe. Ideal for reactions with a consistent reaction rate along the length of the reactor.

Continuous Stirred-Tank Reactors (CSTR): Also known as mixed flow reactors, these have a constant flow of reactants and products with continuous mixing. Suitable for reactions that need uniform composition throughout the reactor.

3. Semi-Batch Reactors:

A combination of batch and continuous operations, where one or more reactants are added continuously or in stages, while the product is removed batch-wise.

Used for reactions that require gradual addition of a reactant to control reaction rate and heat generation.

4. Packed Bed Reactors:

Consist of a packed bed of catalyst particles, through which the reactants flow.

Commonly used in catalytic processes where the reaction occurs on the surface of solid catalysts.

Widely used in petrochemical, pharmaceutical, and environmental applications.

5. Fluidized Bed Reactors:

Solid catalyst particles are suspended in an upward flow of gas or liquid, creating a fluid-like state.

Provides excellent heat and mass transfer, suitable for reactions requiring uniform temperature and catalyst distribution.

Used in processes like catalytic cracking in the petroleum industry.

6. Membrane Reactors:

Combine reaction and separation in a single unit by using a membrane to selectively separate products or reactants.

Enhance reaction efficiency and selectivity, often used in hydrogen production and purification processes.

7. Photo Reactors:

Utilize light (usually UV or visible light) to initiate and drive chemical reactions.

Used in processes like photopolymerization, photocatalysis, and synthesis of fine chemicals.

8. Microreactors:

Miniaturized reactors with small channels or chambers, allowing precise control over reaction conditions.

Suitable for fast, exothermic reactions and research and development of new processes.

Applications of Chemical Reactors

Chemical Manufacturing: Production of bulk chemicals, intermediates, and specialty chemicals.

Pharmaceutical Industry: Synthesis of active pharmaceutical ingredients (APIs) and drug formulations.

Petrochemical Industry: Refining of crude oil, production of fuels, and petrochemical intermediates.

Polymer Production: Manufacture of plastics, resins, and synthetic fibers.

Environmental Applications: Treatment of wastewater, air pollution control, and catalytic converters.

Design and Operational Considerations

1. Reaction Kinetics:

Understanding the rate of reaction and how it changes with concentration and temperature is crucial for reactor design.

2. Heat and Mass Transfer:

Efficient transfer of heat and mass within the reactor is essential to maintain optimal reaction conditions and avoid hotspots or concentration gradients.

3. Material Selection:

The choice of materials for reactor construction must be compatible with the reactants, products, and operating conditions to ensure durability and safety.

4. Safety and Control:

Reactors must be equipped with appropriate safety measures, including pressure relief systems, temperature and pressure sensors, and emergency shutdown systems.

5. Scalability:

The reactor design should consider scalability from laboratory to pilot plant to full-scale production.

6. Cost Efficiency:

Optimizing reactor design and operation to minimize costs while maximizing yield and productivity is essential for commercial viability.

Advancements in Reactor Technology

Catalyst Development: Enhancing catalyst performance to improve reaction rates and selectivity.

Process Intensification: Designing more compact and efficient reactors to increase throughput and reduce energy consumption.

Automation and Control: Implementing advanced control systems for real-time monitoring and optimization of reactor operations.

Sustainable Processes: Developing reactors that use renewable energy sources, reduce waste, and minimize environmental impact.

Chemical reactors are the heart of industrial chemical processes, and their design and operation are critical to the efficiency, safety, and economic viability of chemical production. Understanding the different types of reactors and their specific applications helps in selecting the right reactor for a given process, ensuring optimal performance and sustainability.

| Business Type | Manufacturer, Exporter, Supplier |

| Automation Grade | Semi-Automatic |

| Finishing | Polished |

| Driven Type | Electric |

| Type | Chemical Reactor |

| Material | Stainless Steel |

| Color | Silver |

| Usage/Application | Fluidized Bed |

| Temperature Range | High Temperature Resistance |

| Pressure Range | Suitable For High-pressure Applications |

Reactors

Reactors are critical components in chemical engineering and various industries, designed to facilitate controlled chemical reactions. These reactors come in different types and configurations, each suited for specific reaction conditions and requirements. They play a vital role in the production of chemicals, pharmaceuticals, polymers, and many other products.

Types of Chemical Reactors

1. Batch Reactors:

Operate with all reactants loaded into the reactor at the start, and products are removed after the reaction is complete.

Suitable for small-scale production and processes that require precise control over reaction time and conditions.

Commonly used in pharmaceuticals, fine chemicals, and specialty chemicals.

2. Continuous Flow Reactors:

Reactants are continuously fed into the reactor, and products are continuously removed.

Suitable for large-scale production and processes that benefit from steady-state conditions.

Types include:

Plug Flow Reactors (PFR): Also known as tubular reactors, these have a continuous flow of reactants through a cylindrical pipe. Ideal for reactions with a consistent reaction rate along the length of the reactor.

Continuous Stirred-Tank Reactors (CSTR): Also known as mixed flow reactors, these have a constant flow of reactants and products with continuous mixing. Suitable for reactions that need uniform composition throughout the reactor.

3. Semi-Batch Reactors:

A combination of batch and continuous operations, where one or more reactants are added continuously or in stages, while the product is removed batch-wise.

Used for reactions that require gradual addition of a reactant to control reaction rate and heat generation.

4. Packed Bed Reactors:

Consist of a packed bed of catalyst particles, through which the reactants flow.

Commonly used in catalytic processes where the reaction occurs on the surface of solid catalysts.

Widely used in petrochemical, pharmaceutical, and environmental applications.

5. Fluidized Bed Reactors:

Solid catalyst particles are suspended in an upward flow of gas or liquid, creating a fluid-like state.

Provides excellent heat and mass transfer, suitable for reactions requiring uniform temperature and catalyst distribution.

Used in processes like catalytic cracking in the petroleum industry.

6. Membrane Reactors:

Combine reaction and separation in a single unit by using a membrane to selectively separate products or reactants.

Enhance reaction efficiency and selectivity, often used in hydrogen production and purification processes.

7. Photo Reactors:

Utilize light (usually UV or visible light) to initiate and drive chemical reactions.

Used in processes like photopolymerization, photocatalysis, and synthesis of fine chemicals.

8. Microreactors:

Miniaturized reactors with small channels or chambers, allowing precise control over reaction conditions.

Suitable for fast, exothermic reactions and research and development of new processes.

Applications of Chemical Reactors

Chemical Manufacturing: Production of bulk chemicals, intermediates, and specialty chemicals.

Pharmaceutical Industry: Synthesis of active pharmaceutical ingredients (APIs) and drug formulations.

Petrochemical Industry: Refining of crude oil, production of fuels, and petrochemical intermediates.

Polymer Production: Manufacture of plastics, resins, and synthetic fibers.

Environmental Applications: Treatment of wastewater, air pollution control, and catalytic converters.

Design and Operational Considerations

1. Reaction Kinetics:

Understanding the rate of reaction and how it changes with concentration and temperature is crucial for reactor design.

2. Heat and Mass Transfer:

Efficient transfer of heat and mass within the reactor is essential to maintain optimal reaction conditions and avoid hotspots or concentration gradients.

3. Material Selection:

The choice of materials for reactor construction must be compatible with the reactants, products, and operating conditions to ensure durability and safety.

4. Safety and Control:

Reactors must be equipped with appropriate safety measures, including pressure relief systems, temperature and pressure sensors, and emergency shutdown systems.

5. Scalability:

The reactor design should consider scalability from laboratory to pilot plant to full-scale production.

6. Cost Efficiency:

Optimizing reactor design and operation to minimize costs while maximizing yield and productivity is essential for commercial viability.

Advancements in Reactor Technology

Catalyst Development: Enhancing catalyst performance to improve reaction rates and selectivity.

Process Intensification: Designing more compact and efficient reactors to increase throughput and reduce energy consumption.

Automation and Control: Implementing advanced control systems for real-time monitoring and optimization of reactor operations.

Sustainable Processes: Developing reactors that use renewable energy sources, reduce waste, and minimize environmental impact.

Chemical reactors are the heart of industrial chemical processes, and their design and operation are critical to the efficiency, safety, and economic viability of chemical production. Understanding the different types of reactors and their specific applications helps in selecting the right reactor for a given process, ensuring optimal performance and sustainability.